quietwater paddles pictures

Pictures. At first I worried about the camera getting wet or full of sawdust. I got over that. Now I just take pictures. Carefully. So far so good.

Pictures. At first I worried about the camera getting wet or full of sawdust. I got over that. Now I just take pictures. Carefully. So far so good.

January 5, 2022

One of my favorite paddle pics. I might just be partial to curly redwood. A bit.

Maybe more. The right side paddle is also redwood. Clear, vertical grain redwood.

Encapsulated in four ounce, plain weave fiberglass filled with MAS epoxy. As always, I recommend

a tip guard. Not only does it provide some impact protection, it also seals the end

grain of the blade pieces, which prevents water from being sucked up into the wood.

July 26, 2021

The sky's the limit. With fiberglass and epoxy to strengthen, stiffen, and seal the

wood blade pieces, just about anything can work for the paddle blade. Cotton cloth,

old barn board, walnut, and multi-piece blades are all shown in this picture. And

knots. Did I mention that I really like knots? As a design element they are unique

like snowflakes, no pun intended. At least for me. Also note the walnut for shaft

strips and the style of the shaft strip bottom ends.

Here's one from the 'way back' machine. I built this paddle as a kid back in about

1979. My parents saved it and 'gifted' it back to me. The point simply being that

woodburning is an option for dressing up your blade. All the shaping was done with

a drawknife, which I still have, and which is all I had at my disposal as that kid

back in 1979. Note: spokeshave and Surform are much more pleasant to work with when

shaping paddle shaft and blade.

Walnut edge strips on a white pine blade, with some sort of maple leaf under the epoxy. Can't remember if I put it under the fiberglass or on top of the glass. The grid pattern is from the individual glass fibers. They look like this after the first pour. Adding the second (and smaller) pour of epoxy fills in the remaining grid and the fibers are then completely transparent. Fiberglass and epoxy are a WWII era invention and were the world's very first composite material. For those inclined to appreciate the history of industrial innovation, fiberglass and epoxy are fascinating. They also are one of the first examples of a global product and the requisite licensing and patenting, on a global scale. All back in the WWII era.

It doesn't always have to be cedar. Laminating pieces together greatly increases the

strength of any wood. White pine is easy to work and looks great, especially with walnut

edge strips. At least I think it does. The shaft strips feature a chisel-like end feature

rather than my usual rounded 'snout'. When you build your own paddle, you can shape the end of each shaft

strip however you want!

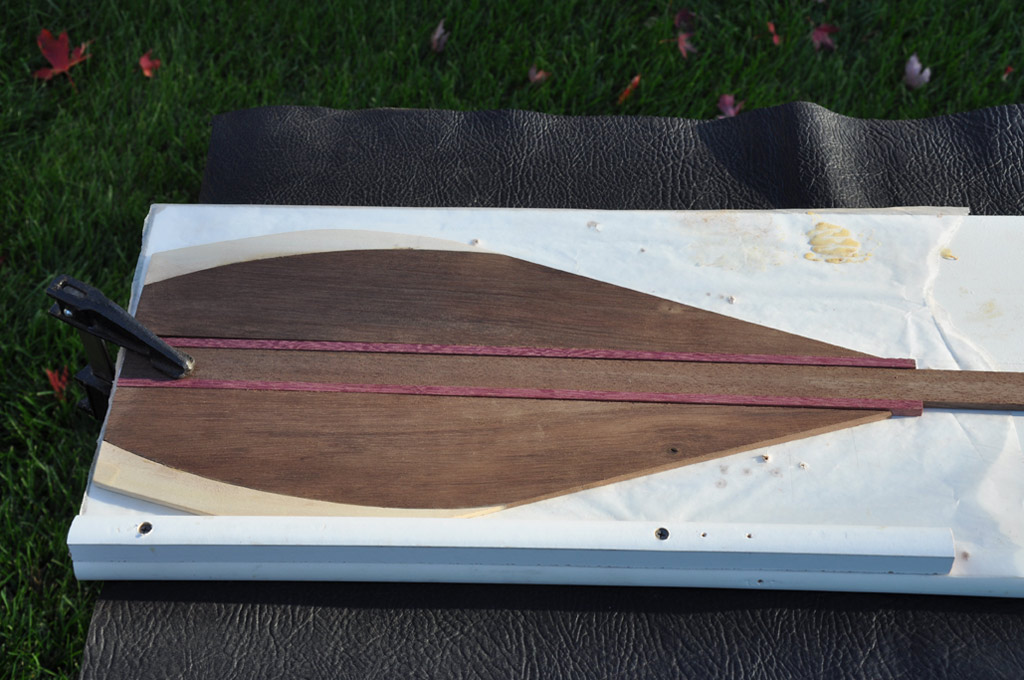

Just getting started here. First step will be tapering the tops of the purpleheart pieces to match the lines of the walnut pieces. Then some epoxy comes out. Then some scraping and maybe a spokeshave.

I like pine. It's simple, nice wood. I like the texture and character that knots add to a blade. So here is a pine and cedar paddle with knotty pine blades. There's a bit of purpleheart in there too.